60 Years, 7 Industries, 5 Different Services

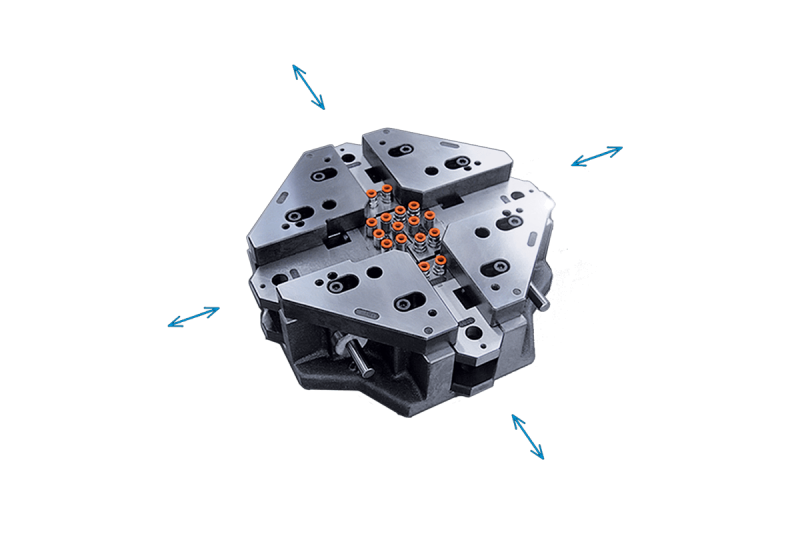

We have over 60 years of experience in providing solutions for different industries. Our services include tool development, casting simulations, design, engineering and production. Tools are tailored to the specific needs of the customer. From high volume production, precision manufacturing, to prototype tools, we provide a complete service.

The tools can be combined with automation systems designed and built in-house. Our team of engineers will provide support during the product development stage with casting simulations and feasibility studies.

Tried and Tested

Our tool-technology is proven and tested over millions of cycles in Titus own manufacturing facilities. We have the capability of solving the most demanding tool problems. The tool-design is efficient, maximizing productivity, lowering production costs with consistent product quality. Close cooperation with our customers ensures continuous development of our engineering competence and an ability to keep pace with the latest technical advancements.

We have already successfully provided solutions for different industries:

| Automotive | Electric | Household Appliances | Metal working | Toy Industry | Die casting industry | Automation systems |

|

turbochargers: housings, cores, volutes |

axels |

washing machine door hinge |

furniture connectors |

manual typewriter |

tools |

standard modules |

Full Customer Support

Our team of engineers will provide support during the product development stage with casting simulations and feasibility studies. But our customer support service doesn't end there: we will accompany you during the implementation phases and after the tool is in production as well.

Subscribe to our newsletter

Subscribe to our newsletter and be among the first to learn about our latest products, state-of-the-art innovations and company-related news.