Our totally integrated approach underpins everything that we stand for. From end to end, our integrated engineering puts the customer front and centre, always keeping them in mind to ensure we deliver an effective, problem-solving end result.

To do this, we combine our customer-led research and development with lean processes and state-of-the-art manufacturing operations. Each stage of the innovation and production process is strategically managed. From formalising new product concepts and developing prototypes to manufacturing and bringing to market components that solve real industry problems, every step is fully integrated.

Our integrated offering is made up of three main areas of expertise – product design, technologies and manufacturing operations. Each area supports and creates added value for the other two, and together they result in quality precision components. Here’s a little more about the key areas.

Product design.

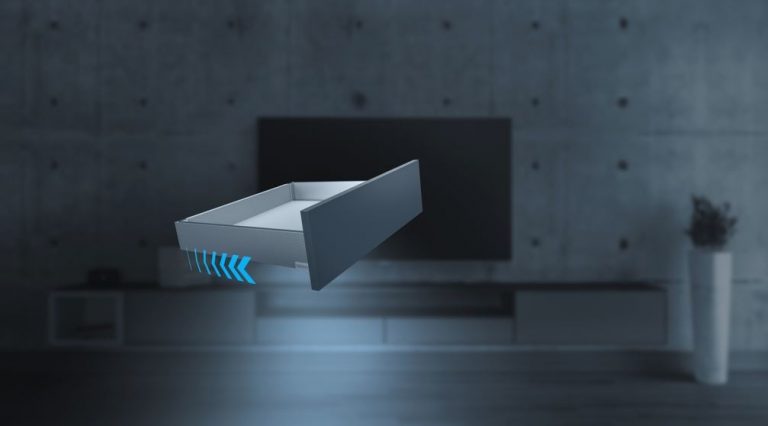

We design and engineer unique components that are consistent and repeatable in both quality and performance.

Manufacturing technologies

We combine state-of-the-art technologies with tried and tested manufacturing processes to improve productivity and product quality.

Manufacturing operations

With an extensive in-house manufacturing operation, we are best placed for high-volume production of a range of precision components.