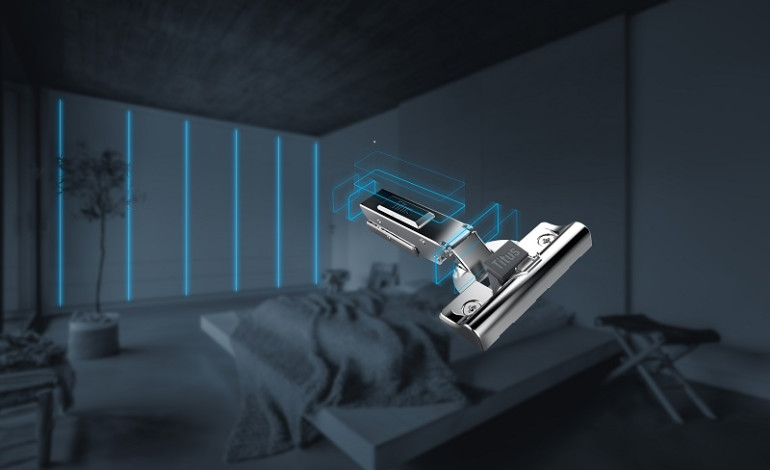

Precision engineering and safety

We know that safety is uncompromisable when it comes to cabinet and furniture hardware. We serve some of the biggest kitchen, bathroom and furniture manufacturers in the world, so we know we need to provide quality. That’s why we’re constantly working towards producing the very best components in the industry, designed for quality and safety.

Here’s how precision-engineered components from Titus help increase safety.

Streamlined assembly process

Our components are designed for quick and easy assembly. By featuring intuitive designs that are easy to put together, we help reduce the chance of assembly errors and minimise the need for complex tools – creating a smoother and safer assembly process.

Reduced human error

Our components are straightforward to install, making them less prone to misalignment or incorrect installation. This reduces the risk of incorrectly assembled furniture, which could have compromised stability and lead to accidents during use.

Enhanced stability

Our components fit precisely and securely together during assembly, resulting in furniture with much better stability. The result is less chance of wobbling or tipping during use, which could then result in falls or injuries.

Rigorous testing

As our components are all designed for lifetime performance, they are rigorously tested to ensure that they can handle certain weights, loads and stresses. This testing ensures the furniture remains structurally sound and safe even when bearing weight or under stress.

Durable materials

Our components are made from high-quality, durable materials that can withstand heavy use. That means that they will maintain structural integrity over time, reducing the risk of any unexpected failures or breakages.

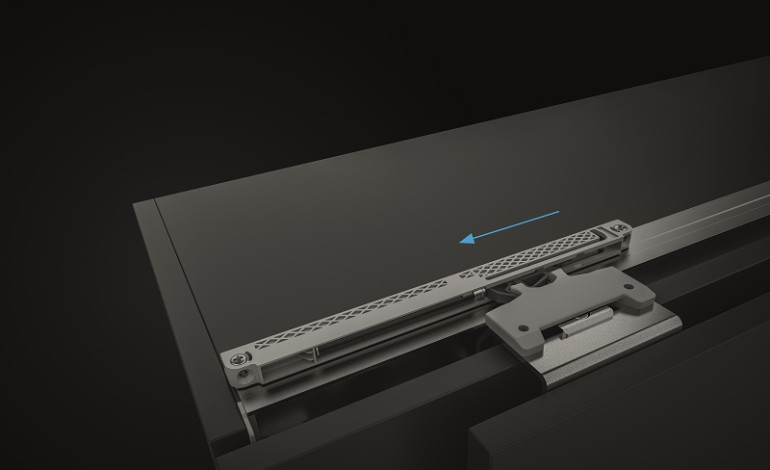

Preventing accidents

Our furniture dampers help improve safety through smooth motion control. Components with soft-close mechanisms improve safety by preventing doors or drawers from slamming shut. This hugely reduces the risk of trapped fingers and other injuries – particularly in homes with young children.

Consistency

Because our components are made with precision and durability in mind, they’re designed to offer consistent performance and meet strict standards and regulations. This provides peace of mind to end users and manufacturers alike that the resulting furniture adheres to safety requirements.