Titus Precison Plastics, based out of Columbia City, IN, brings over 60 years of manufacturing experience and a long history supplying the Automotive, Defense, and Healthcare sectors.

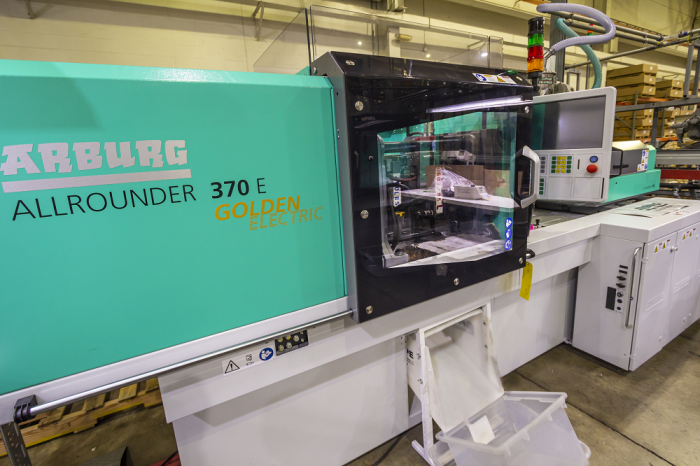

Machine capabilities

| Up to 150 Ton | 6 Machines |

| 151 to 200 Ton | 6 Machines |

| 301 to 450 Ton | 6 Machines |

| 60 Ton | 2 (NEW) Electric Machines |

| 110 Ton | 1 (NEW) Electric Machine |

Key features of Titus Precision

- High level of product quality and service

- Automation, Poka Yoke, and 30+ years experience in precision manufacturing

- Project management expertise

- Application Development Sales Engineers as key contact point

- Strategic location and loyal workforce

- Injection molding, zinc die casting and automated assembly in-house

- Quality systems

- Strength as a member of Titus Global Business Group

The six-phase disciplined approach

Technical support to customers from initial concept through life cycle of production.

| 1. Quotation: | Identify methods, machinery, manpower, and materials |

| 2. Project and Quality Planning: | Including process development and validation |

| 3. Project Management and Development: | Including design reviews, capacity planning, packaging, quality documentation, project status tracking |

| 4. Process Development and Validation: | Trial runs, testing, capability studies, dimensional layouts, and PPAP |

| 5. Process Acceptance: | “Run at Rate”, “Lessons Learned Review” |

| 6. Program Maintenance: | Quality reviews, continuous improvement, VAVE |

Custom molding quality systems

- UL Registered B-1151

Innovative automation capabilities

- Robot and Camera Automation

- Specialty Automated Assembly Machines

Titus Precision – Zinc die casting

Titus Group builds our die-cast machinery, which is ideal for manufacturing small zinc parts.

Benefits and capabilities

LamaCaster P65 proprietary MultiSlide die casting machines are ideal for small zinc parts due to:

- Speed

- Repeatability

- Tight Tolerances

- Die Size: 65 x 65mm (approx. 2.56 x 2.56 in.)

- Clamping force – 3.2 tonnes

- Shot weight: 60 grams (2.11 ounces)

- Dry Cycle Speed: 100 cycles per minute

- Casting Speed: 55 cycles per minute

US Manufacturing Facility

Contact Titus Precison

To get in touch with our US-based sales team, call us at 260-244-6114

Email: [email protected]